JFT600D

1. The whole bed is made of HT250 one-piece casting and aged. The whole machine weighs 1.4 tons. It has strong rigidity and good stability.

2.Taiwan grinding screw, P-level guide rail,Guangzhou KY CNC system , Taiwan LNC servo motor, and fine grinding table.

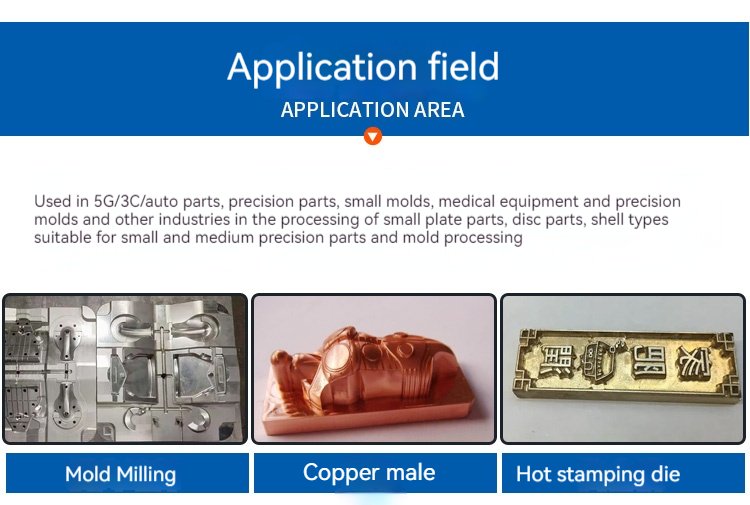

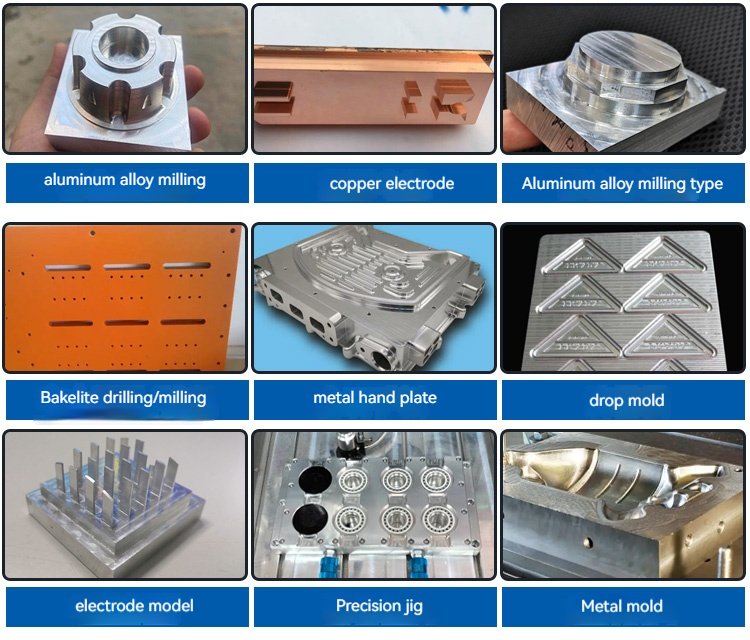

3. It can be used for milling, drilling, chamfering, tapping, curved surface and other precision machining of metal and non-metallic materials.

4.Recommend the use of products/molds requiring multi process processing, and the automatic tool change of tool magazine can improve efficiency and reduce cost.

Specification

| Specifications | JFT600 | JFT600D | ||

| X axis(mm) | 600 | 550 | ||

| Y axis(mm) | 600 | 600 | ||

| Z axis(mm) | 200 | 200 | ||

| Spindle end face to workbench(mm) | 50-250 | 50-250 | ||

| X/Y/Z rapid movement(mm/min) | 10000 | 10000 | ||

| Cutting feed(m/min) | 50-8000 | 50-8000 | ||

| Three axis servo motor torque | 750W Servo motor ( INOVANCE) | 750W Servo motor ( INOVANCE) | ||

| Control system | Guangzhou KY CNC system | Guangzhou KY CNC system | ||

| Table area(mm) | 640x640x40 | 640x640x40 | ||

| Table bearing(kg) | 300 | 300 | ||

| T-groove(mm) | M10*50mm | M10*50mm | ||

| Spindle speed(rpm/min) | 24000 | 24000 | ||

| Spindle taper hole | ER25/20 | BT30-ER25 | ||

| Spindle power(kw) | 4.5 | 5.5 | ||

| Tools cheange capacity | / | 6T | ||

| Tools cheange time | 5s | 5s | ||

| Votalge | AC380V | AC380V | ||

| Positioning accuracy(mm) | 0.01 | 0.01 | ||

| Repeat positioning accuracy (mm) | 0.008 | 0.008 | ||

| Machine dimension(mm) | 1300x1600x1980 | 1300x1600x1980 | ||

Image Gallery

Features & Benefits

1.High Precision Machining Capability: Utilizes high-quality components such as Taiwan grinding screws and P-level guide rails, combined with the overall casting and aging of the bed, ensuring high-precision machining results to meet the demands of precision engineering.

2.Strong Stability and Rigidity: Weighing 1.4 tons and featuring a one-piece cast bed treated for stability, it offers exceptional rigidity and stability, maintaining surface quality and machining precision even during high-speed operations.

3.Versatile Machining Capabilities: Supports milling, drilling, chamfering, tapping, curved surface machining, and more, catering to the precision machining needs of both metallic and non-metallic materials, providing flexible machining options.

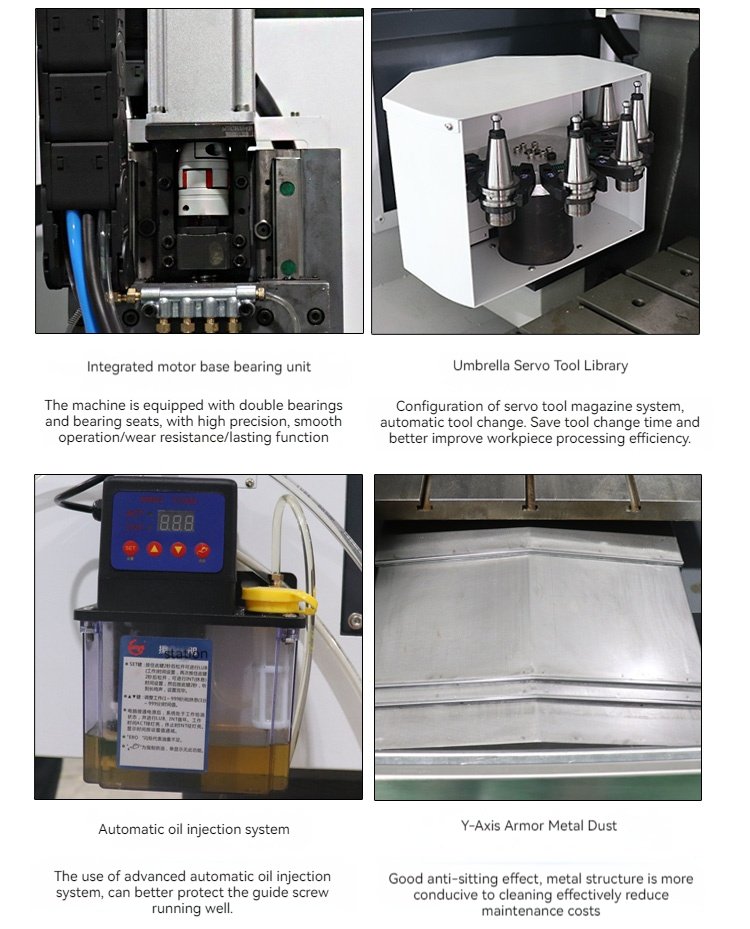

4.Automatic Tool Change System: Equipped with an automatic tool change system in the tool magazine, facilitating quick and automated tool changes, thereby enhancing production efficiency and reducing machining costs.

5.Wide Range of Applications: Recommended for products or molds requiring multi-process machining, it offers excellent versatility and suitability across various industries, meeting diverse machining requirements.

6.Reliable Component Sourcing: Incorporates components from renowned brands such as Taiwan grinding screws, Guangzhou KY CNC system, Taiwan LNC servo motor, ensuring reliability and stability in operation.

More Product Details

Precision Engineering: At the heart of our CNC machining center lies a robust construction featuring an HT250 one-piece cast bed, meticulously aged to ensure maximum stability and rigidity. Paired with Taiwan grinding screws and P-level guide rails, the machine guarantees high-precision machining results, meeting the stringent requirements of precision engineering projects.

5.5KW tool change spindle Absolute value of bus

manual tool change

5.5KW tool change spindle motor, eliminating Support high-resolution axial motor, improve machining efficiency,motion smoothness,strong

Cost.Work efficiency is greatly improved anti-interference ability

Umbrella Servo Tool Library Integrated motor base bearing unit

The servo mator rotates directly, which can rotate and it is more stable and reliable without cylinder,360 degrees at will. The tool change efficiency is high long-lasting function and smooth operation,wear resistance and The machine is equipped with double bearing seats, which are closely fitted, with high precision

- JIE FENG TAI

Factory Display

Certificates & Trademarks

Certificates & Trademarks

- Efficient Production Facilities: Equipped with state-of-the-art machinery and technology, our factory ensures streamlined production processes, maximizing output while maintaining high quality standards.

- Optimized Logistics Network: With a well-established logistics network, we guarantee timely delivery of products to our customers, ensuring that orders are fulfilled promptly and efficiently.

- Dedicated Customer Service: Our team of dedicated customer service professionals is committed to providing personalized support and assistance, ensuring a smooth and hassle-free experience for our clients.

- Customized Solutions: We offer tailor-made solutions to meet the unique needs and requirements of each customer, providing flexibility and adaptability to diverse project specifications.

- Robust Supply Chain Management: Leveraging strong relationships with reliable suppliers, we ensure a steady and uninterrupted flow of materials, minimizing production delays and optimizing inventory management.

- Quality Assurance: Committed to delivering products of the highest quality, our factory adheres to rigorous quality control measures throughout the production process, guaranteeing consistency and reliability in every batch.

- Continuous Improvement Initiatives: We prioritize continuous improvement and innovation, constantly seeking ways to enhance our production processes, logistics efficiency, and customer service standards.

- Responsive Problem-Solving: In the event of any issues or challenges, our proactive problem-solving approach ensures swift resolution, minimizing disruptions and maintaining customer satisfaction.

Feedbacks From Our Clients